Welcome to Dynemech Systems Pvt. Ltd

SCREW DLM

583.0 INR/Piece

Product Details:

- Hardness High strength

- Finish Galvanized

- Product Type SCREW DLM

- Material High grade steel

- Function Secures components by fastening

- Usage For industrial and machinery use

- Weight Lightweight

- Click to View more

X

SCREW DLM Price And Quantity

- 4 Piece

- 583.0 INR/Piece

- 100000.00 - 500000.00 INR/Piece

SCREW DLM Product Specifications

- High grade steel

- Metallic Silver

- Customized as per requirement

- High strength

- Galvanized

- Lightweight

- Automotive, construction, mechanical engineering

- For industrial and machinery use

- Secures components by fastening

- Rust resistant, durable, high precision thread

- SCREW DLM

SCREW DLM Trade Information

- 1000 Piece Per Day

- 3 Days

Product Description

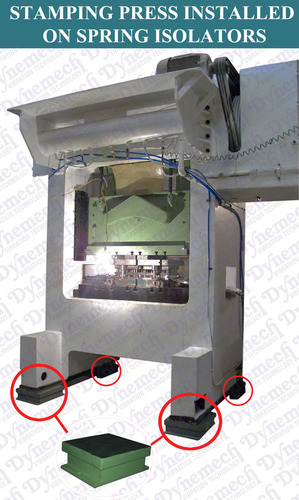

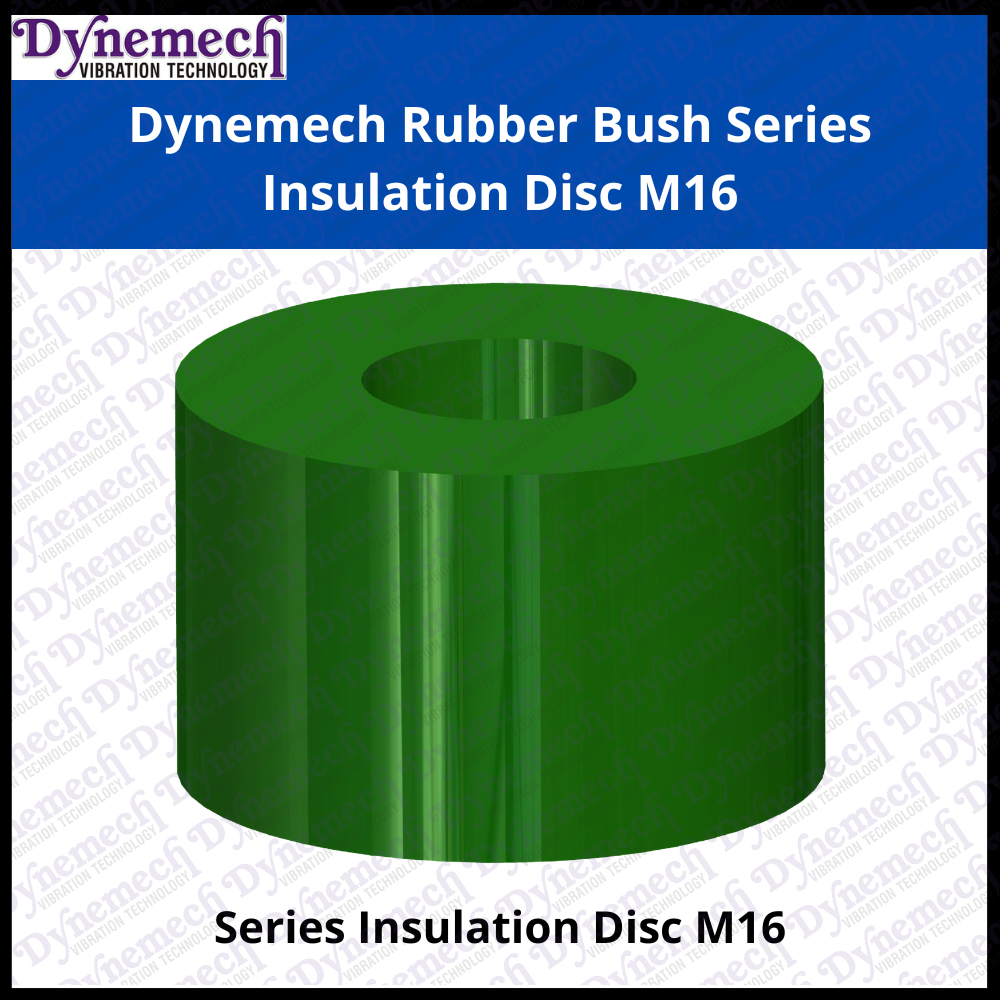

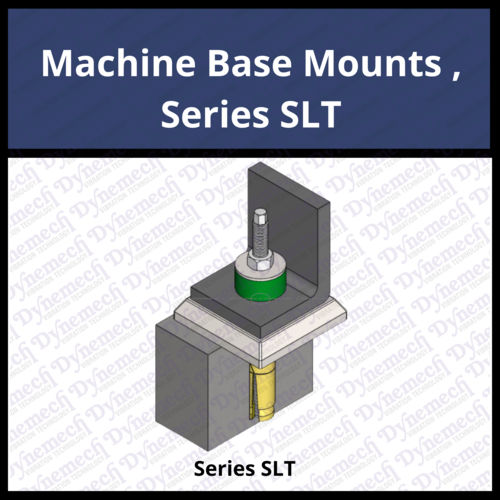

Dynemech DLM Series Mounts, developed in steel and stainless steel respectively are simple and effective vibration dampers for machines with respective holes in the base. these mounts offer low frequency attenuation, stable machine levelling and vibration reduction. The Flexible levelling screw accommodate uneven/sloped surfaces upto 5. DLM series find application where corrosion resistant materials for hygienic, climatic and environmental reasons are required like in pharmaceutical, food and beverages processing and packaging units, medical equipments manufacturing and chemical processing industries.Precision Engineered for Industrial Excellence

SCREW DLM combines innovative engineering and strict ISO standards to deliver superior fastening components. With high precision threads and a robust galvanized surface treatment, these screws serve reliably in high-stress environments. Their rust-resistant and durable finish makes them ideal for both new installations and repairs in industries such as automotive and construction.

Versatile Customization to Meet Unique Needs

Clients benefit from extensive custom options, including size, diameter, and surface finish, all tailored as per technical drawings provided. Whether packaged in bulk or individualized boxes, SCREW DLM products adapt to specific operational demands, ensuring efficient supply for distributors, exporters, and manufacturers.

FAQ's of SCREW DLM:

Q: How can I select the appropriate SCREW DLM for my application?

A: Choose your SCREW DLM based on thread type, head configuration, diameter range, and intended usage. Our experts can assist in matching your exact technical specifications for automotive, construction, or mechanical engineering environments.Q: What packaging options are available for bulk orders?

A: SCREW DLM screws are available boxed for organized storage or in bulk packaging for large-scale operations. You may specify your preferred packaging when placing an order to streamline inventory management.Q: Where is SCREW DLM manufactured and supplied from?

A: SCREW DLM is produced in ISO-certified facilities in India, supplied globally to distributors, importers, exporters, and manufacturers across different industries.Q: When can I expect order fulfillment for customized screws?

A: Customized orders are typically fulfilled within 2-4 weeks, depending on the complexity of your technical drawing and required specifications. Our team provides accurate lead time estimates upon order confirmation.Q: What corrosion protection does SCREW DLM offer?

A: Each screw features a zinc-plated, galvanized surface, providing strong resistance against rust and corrosion even in challenging environments, ensuring the longevity and reliability of secured connections.Q: How does using SCREW DLM benefit industrial operations?

A: SCREW DLM fasteners provide high tensile strength and temperature resistance up to 400C, guaranteeing secure component fastening, reduced maintenance needs, and operational reliability in demanding conditions.Q: What is the process for customizing SCREW DLM screws?

A: Customization begins with submitting your technical drawings and specifications. Our engineers review requirements and produce your order according to ISO manufacturing standards, delivering accurately tailored fastening solutions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese