|

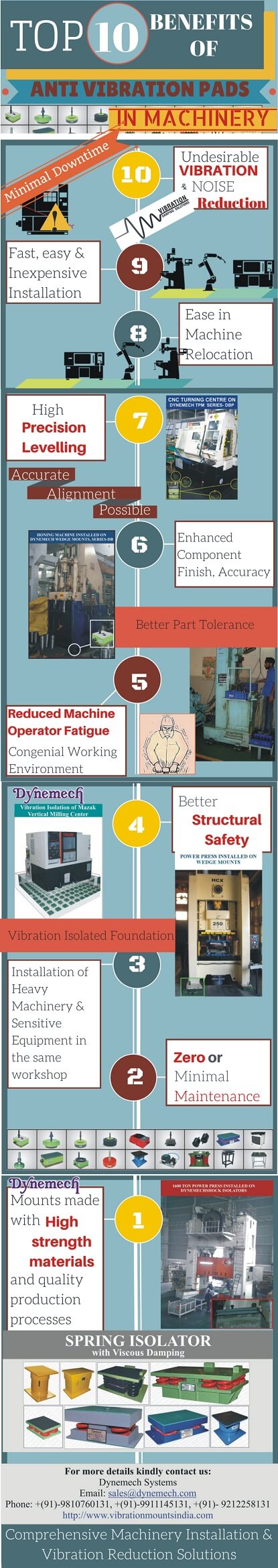

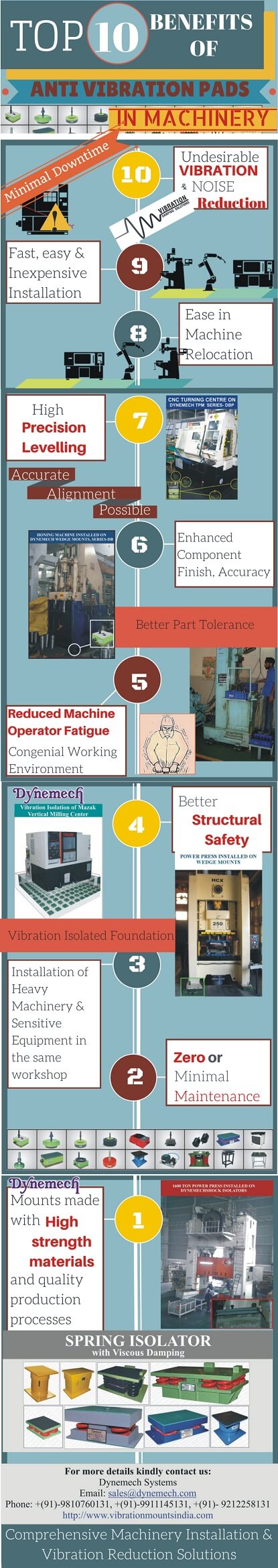

Machineries in the production process nowadays sometimes need to run maintenance free 24x7. Moreover, World Class Manufacturing, overall machinery efficiency, as well as the improvement of productivity and quality, has become a hallmark of manufacturing setups. Production methods that improve efficiency and reduce costs, such as lean manufacturing and just-in-time production, are more commonplace. Modern manufacturing practices provide higher part accuracy and productive efficiency to ultimately maximize profit. With DYNEMECH Anti Vibration Technology and Machinery Installation Solutions, we make it easy for you to be competitive in the global manufacturing environment, which has become the norm.

- Quick, Convenient and Economical Machinery Installation - Even on machines with little downtime.

- Flexible Shop Floor Plan, Facilitates expansion plans & technology introductions - Permanent mobility of machines.

- Enhanced Finish, Accuracy and Tolerance of Components improved production quality -No "chattering" marks.

- Extended Life of Tool And Machinery, Ensuring equitable profits from investments in machinery.

- Vibrations cause fatigue and failure in machinery and tools. As gears, bearings and other machine parts wear and tear, as well as excessive noise, normal production processes may be gradually hampered. Vibration control is necessary to prevent machinery damage, unscheduled maintenance and costly downtime.

- Improved Health Protection of Workers - reduce machine operator fatigue & accident risks by reducing continuous vibrations.

- OSHA guidelines on Ergonomics Program and European Directive 2002/44/EC cover vibration exposure because of its impact on the health and safety of workers, namely muscular/bone structures, neurological and vascular disorders, requiring employers to control vibration exposure.

- Environmental nuisances reduced-providing a more pleasant working environment.

- Better Structural Safety due to reduction in vibration transmission.

- Composite rubber insulation plates for shop floors that can withstand moisture, most fuels, lubricating oils, acids, and more.

- Reduction in unwanted Vibration and Noise in manufacturing setups.

- Vibration-isolated foundations make installation of sensitive quality control and testing equipment and heavy production machinery possible in one workshop.

- All industrial machines should be mounted within the recommended range of 100 - 150mm in height to facilitate routine Autonomous Maintenance activities like cleaning, minor repairs, and general inspection. (IMTMA Guidelines for Machines with TPM Features,2004).

- With minimal or no damage to the flooring, new installations have optimal space utilization and reduce substructure costs substantially.

- It is possible to level and align plant machinery with high precision.

- The idea of installation on upper floors becomes feasible without causing damage or vibration transmission to building structures or foundations.

- A favourable price-to-performance ratio is offered by Dynamech anti-vibration mounts.

- A CNC, CMM, and quality control equipment equipped with digital or electronic panels and microprocessors will only function at optimal accuracy in a vibration-free environment. To accurately measure, operate at the ideal speed, and ensure good quality, vibration isolation becomes essential. Costs associated with the entire product life cycle are drastically reduced, as are set up times, adjustment losses, and unscheduled downtime.

- Dynemech anti-vibration mounts are the solutions to the resonance and vibrations problems. These systems get a phase difference of vibratory frequency in rotating machines, as well as extending the vibration period of flexibly mounted machinery systems.

- These anti-vibration mounts are constructed from high-quality materials and manufactured according to high-tech processes; they are very low maintenance and last for many years.

- Ensures compliance with OSHA regulations on anchoring fixed machinery to prevent moving or walking.

- Our broad range of solutions is for anchored and freestanding machines with varied weight capacities, covering almost every industrial application.

- Its unique cell design and high coefficient of friction allow it to adhere well to the ground, preventing "machine walking".

|

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese