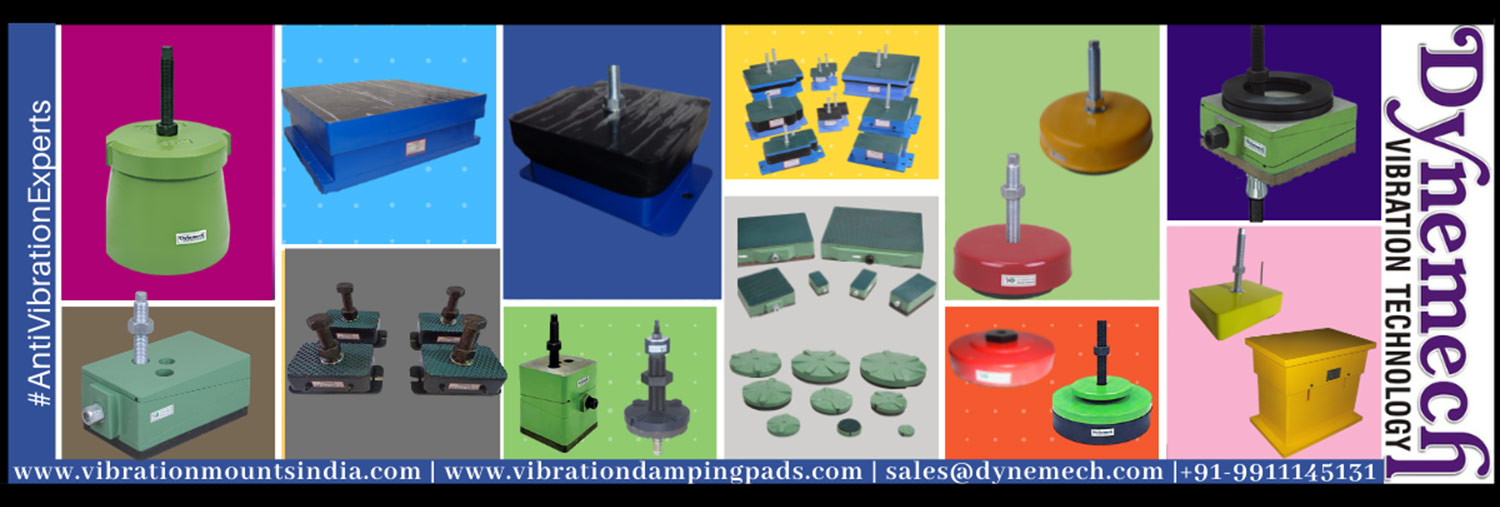

Welcome to Dynemech Systems Pvt. Ltd

Dynemech Systems Pvt. Ltd.: Pioneering Anti Vibration Pads & Vibration Control Solutions Since 2000.

Established in 2000, Dynemech Systems Pvt. Ltd. has emerged as a leading innovator and manufacturer and highly reputed exporter, manufacturer, wholesaler/distributor, supplier and trader in the field of vibration control technology and anti-vibration pads . With over two decades of expertise, we specialize in developing and producing a comprehensive range of anti-vibration solutions for diverse industrial applications.

Established in 2000, Dynemech Systems Pvt. Ltd. has emerged as a leading innovator and manufacturer and highly reputed exporter, manufacturer, wholesaler/distributor, supplier and trader in the field of vibration control technology and anti-vibration pads . With over two decades of expertise, we specialize in developing and producing a comprehensive range of anti-vibration solutions for diverse industrial applications.

Our Anti Vibration Product Portfolio

- Anti Vibration Insulation Plates & Sheets: Vibration Insulation plates

- Anti Vibration Pads: Wedge Mounts Taper Shim Levelling Pads CushyFoot Mountings Rubber Buffers

- Anti-Vibration Mounts: Precision Levelling Mounts High Alignment Anti-Vibration Mounts Machinery Fixators Circular Bolt Supported Machinery Mounts

- Levelling Mounts: Square Levelling Mounts Circular Levelling Mounts Machinery Mounts

- Advanced Vibration Isolation Systems: Pneumatic Vibration Isolators Self-Levelling Membrane Air Springs Spring Viscous Dampers Enclosed Spring Isolators

- Specialized Solutions: Custom-Designed Anti-Vibration Tables Vibration Isolated Workstations Precision Measuring Metrology Instrument Tables CMM Cradle Platform with Pneumatic Vibration Isolators

- HVAC Spring Isolators: Round Spring Elements with Viscous Damping Housed Spring Isolators Restrained Spring Isolators Open Spring Hangers Floor Mounted Spring isolators Spring Viscous Dashpot

- Precision Tools: Roller Burnishing Tools Internal and External Burnishing Tools

Industries Served

Our vibration damping technology caters to a wide spectrum of sectors, including:

- Heavy Industrial Equipment

- Precision Manufacturing

- Automotive and Aerospace

- Metrology and Quality Control

- Research and Development Facilities

- Power Generation and Compression Systems

- Sheet Metal Industry

- Testing and Measuring Industry

- Solar Power and Semi-Conductor Manufacturing Industry

- Pharmaceutical , Life sciences, Bio Medical Research Technology

- Food and Beverages Industry

- Plastic and Packaging Industry

- Defence and Railways

Core Competencies

- Indigenous Innovation: At the heart of Dynemech's success is our commitment to indigenous development. Our in-house R&D team continually pushes the boundaries of vibration control technology, creating solutions that are both cutting-edge and tailored to the customer and machinery installation requirements.

- Customization Capabilities: We understand that each industrial setup has unique vibration challenges. Our engineering team excels in designing and manufacturing bespoke anti-vibration solutions that address specific client requirements, ensuring optimal performance and productivity.

- Comprehensive Vibration Management: From individual mounts to complete vibration-isolated workstations, we offer end-to-end solutions that transform industrial workspaces. Our products not only dampen vibrations but also enhance precision, extend equipment lifespan, and improve workplace ergonomics.

- Quality Assurance: Rigorous quality control measures, including advanced testing and inspection protocols, ensure that every Dynemech product meets the highest standards of performance and reliability.

- Technical Expertise: With over 20 years of experience in the field, our team of skilled engineers and technicians provides unparalleled support, from initial consultation to after-sales service.

Impact and Benefits

- Fast and easy installation

- Flexible shop floor plan

- Enhanced component finish and part - tolerance

- Extended tool and machinery life

- Improved Health protection

- Better Structural Safety

- Enhanced Precision in Manufacturing and Metrology

- Reduced Maintenance Costs

- Improved Workplace Safety and Comfort

- Optimized Performance of Sensitive Machinery and Instruments

- Customized Solutions for Challenging Industrial Environments

ROLLER BURNISHING is a cold working process in which highly polished and hardened rollers roll over the surface and high peaks of the surface roughness cold flows into the cavities, thereby imparting smooth surface finish of the order of 0.05 micro.m Ra and close dimensional tolerance. The benefits it imparts to the manufacturing process and surface are as follows:

- Low Production Cost

- Close Dimensional Tolerance

- Work Hardened and Wear Resistance Surface

- Smooth low microinch surface finish

- Fatigue & Corrosion Resistant Surface

- Internal dia, External dia, Tapered, Radius and Flat parts of steel, cast iron, aluminium, bronze etc of hardness up to 35 HRC can be quickly roller burnished

|

|

At Dynemech Systems, we are not just manufacturing products; we're engineering productivity, precision, and peace of mind for industries across the globe. Our commitment to innovation, quality, and customer satisfaction has established us as a trusted partner in vibration control technology.

Partner with Dynemech Systems to experience the transformative power of advanced vibration management in your industrial operations. Let us help you create stable, efficient, and high-performance work spaces that drive your business forward.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese