Welcome to Dynemech Systems Pvt. Ltd

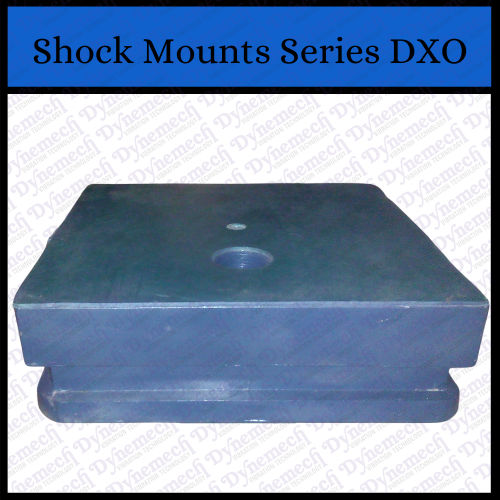

Prefabricated Anti Vibration Mounts

930 INR/Piece

Product Details:

- Application Machinery, Equipment, HVAC Systems

- Noise Level Reduced db

- Material Steel

- Computerized No

- Automatic Grade Manual

- Drive Type Manual

- Feature Low Noise

- Click to View more

X

Prefabricated Anti Vibration Mounts Price And Quantity

- 930 INR/Piece

- 100 Piece

- 100.00 - 500.00 INR/Piece

Prefabricated Anti Vibration Mounts Product Specifications

- Machinery, Equipment, HVAC Systems

- Reduced db

- Manual

- Low Noise

- Green

- Steel

- No

- Manual

Prefabricated Anti Vibration Mounts Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 100 Piece Per Day

- 2-3 Days

- Western Europe, Australia, Eastern Europe, Middle East, South America, Asia, Central America, North America, Africa

- All India

Product Description

Anti Vibration Pads

Vibrations are present in every industrial application, involving machines. Increased speed, feed and cutting rates in precision machine tools and higher impact force and speeds in metal forming machines has invited the need for anchor free flexible installation of machines. The range of Dynemech anti vibration pads is designed taking in to consideration different dynamic behavior of modern machine tools. Damping either achieved through elastomeric mountings or spring isolators limits resonant response

peaks when a machine momentarily passes through

resonance such as during start-up.

Vibration Damping is thus achieved as the property of the

elastomeric, pneumatic or spring-viscous material and is further affected by the character of the dynamic oscillatory input signature of each machinery.

Dynemech Anti Vibration Pads provide fast and easy installation of machines, flexible shop floor plan, enhanced component finish/part tolerance, extended tool and machinery life, improved health protection, better structural safety.

In our product range we manufacture Wedge Mounts, Bolt Supported Mounts, Rubber Air Springs. Depending upon the application insulation plates are selected and assembled for vibration reduction. These Insulation Plates are made of composite material at varying composition give different natural frequencies to provide solutions to all types of industrial machines. These Insulation plates are resistant to water, almost all the coolants ,chemicals, fuels, lubricating oils used in the modern machine shop. These plates will not deform plastically, if the weight of machine does not exceed maximum load value of the insulation plates

Our pads finds application in machines viz. Machining/Turning Centres, Grinding Machines, Boring Machines, Lathes, Shearing Machines, Power Presses, Pressure Die Casting Machines, Plastic Injection Moulding Machines, Tool Room Machines, Measuring and Testing Machines/ Equipments. Powder/Bottle Filling Machines, Packaging/Printing Machines, Pharmaceutical Machines, Textile Machines, Compressors, Gen. Sets, forging hammers etc.

Specification

|

Model |

Max. Load (kg) |

D mm |

H mm |

d mm |

Levelling Adjust. mm |

Natural Frequiency at Max. Load (Hz) |

Bolt |

|

DML1 |

175 |

50 |

40 |

32 |

10 |

7 |

M10 |

|

DML 2 |

500 |

80 |

46 |

45 |

12 |

7 |

M12 |

|

DML 3 |

1200 |

120 |

52 |

60 |

12 |

7 |

M16 |

|

DML 4 |

2000 |

160 |

56 |

90 |

15 |

8 |

M16 |

|

DML 5 |

4000 |

200 |

65 |

120 |

15 |

8 |

M20 |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese