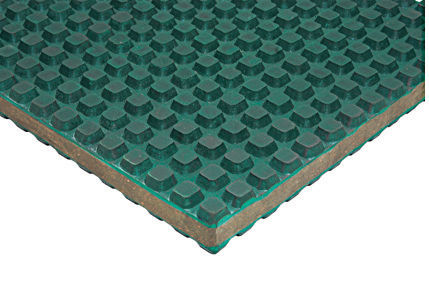

Rubber Vibration Damper

Product Details:

- Product Type Rubber-Vibration-Damper

- Material Steel

- Function Easy To Use

- Usage For Laboratory And Industrial Use

- Color Green

- Click to View more

Rubber Vibration Damper Price And Quantity

- 100 Piece

- 100.00 - 500.00 INR/Piece

Rubber Vibration Damper Product Specifications

- Rubber-Vibration-Damper

- Easy To Use

- Green

- Steel

- For Laboratory And Industrial Use

Rubber Vibration Damper Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 100 Piece Per Day

- 2-3 Days

- Western Europe, Asia, Eastern Europe, Middle East, Central America, South America, North America, Australia, Africa

- All India

Product Description

Rubber-Vibration-Damper

Dynemech has successfully installed many press brakes on wedge mounts or vibration dampers to ensure flexible installation, improved machinery performance, excellent vibration damping along with precision alignment and levelling. High coefficient of friction of assembled insulation plates in vibration dampers prevent machine walking to adhere to OSHA criteria for machinery installation. And of course, our anti vibration pads or vibration dampers are ROHS-compliant and are exported to many countries.

Dynemech Vibration dampers (also called vibration absorbers or vibration isolators) reduce low and high frequency vibrations in machines, systems and structures. The function of Series DT vibration damper is based on a spring/mass system, which counteracts and reduces extraneous vibrations along with self generated excitations. Selecting the wedge type levalators depending on the disturbing frequency and the weight of the machine, high level of vibration damping can be achieved.

This sliding wedge application enables leveling compensation for the machinery besides damping unwanted vibrations without time-consuming machinery installation work. Optimum leveling accuracy and precise machinery alignment requirements make Series DT wedge vibration dampers ideal for use in all kinds of heavy machinery and machine tool components. Series DT wedge vibration mounts also ensure rigid integration of machinery to the foundation and optimum support to the machines during installation and operation.

Typical Applications of DT Series Vibration Dampers:

- -Long Bedded Machines

- -Large Boring Machines

- -Milling and Drilling Machines

- -Machining Centers

- -Long Lathes

- -Long Planers

- -Power presses

- -Press Brakes

- -SPMs

- -Rolling Mills

- -Transfer Machines

- -Grinding Machines

- -Large Compressors-transformers

Also, it needs to be noted that vibration isolation of machinery through use of vibration dampers to prevent the transmission of vibration and noise has become one of the pre requisites to modern workshop building and layout planning. Light weight construction and the need to install mechanical equipment on upper floors, adjacent to quiet areas makes it imperative to control vibration through vibration dampers. Furthermore, rising space rentals many a times, necessitates developing testing and quality control labs nearby sheet metal fabrication shop floor, where operations may be hampered because of vibrations. Thus to ensure productive profitability from our machinery, machines need to be installed on Dynemech Vibration Dampers to ensure vibration damping.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese