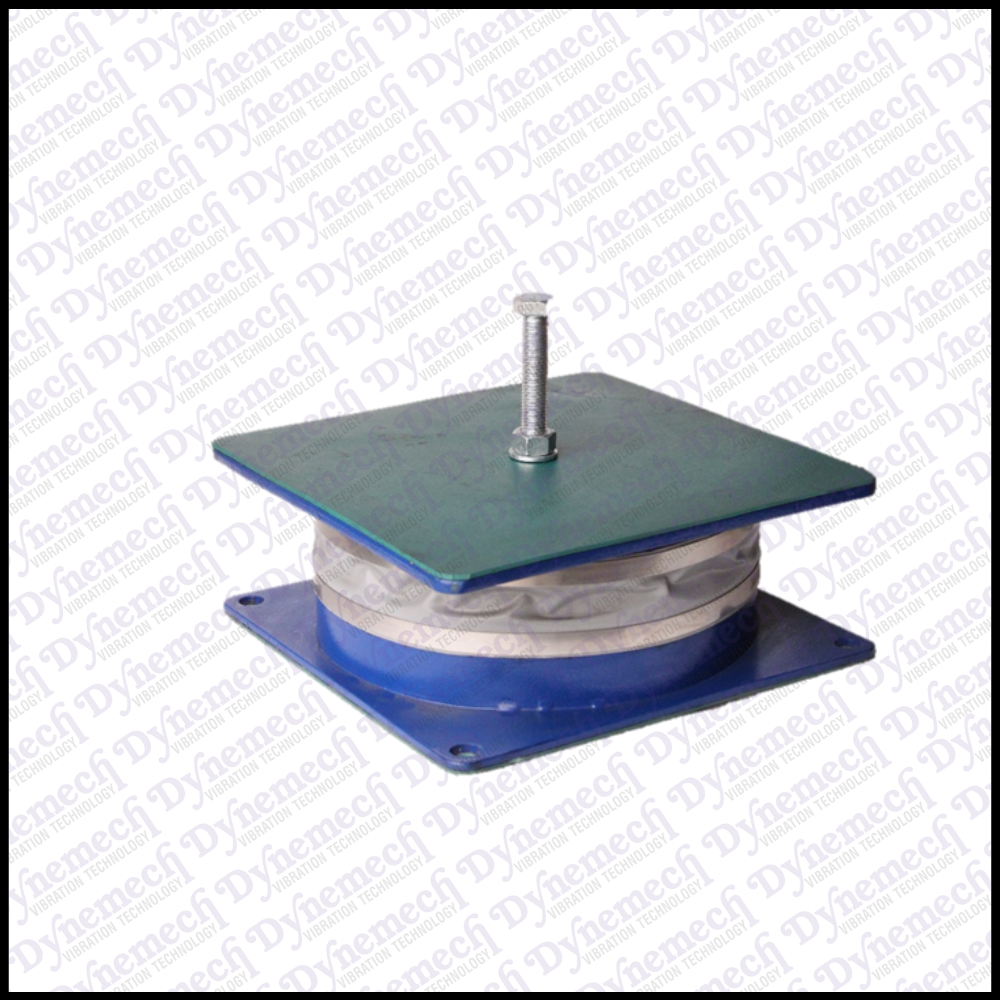

Industrial-Strength Press Mounting Solutions, Series-RBD-RT

Product Details:

- Spring Type ROUND AS PER PHOTO

- Material Iron, Rubber, Natural Rubber, synthetic rubbers

- Height Hi - 98 to 108 mm, Millimeter (mm)

- Function REDUCING VIBRATION

- Product Type VIBRATION CONTROL

- Usage ALL INDUSTRIAL SETUPS

- Weight Load Capacity : 50 to 2800 kg/pc Kilograms (kg)

- Click to View more

Industrial-Strength Press Mounting Solutions, Series-RBD-RT Price And Quantity

- 4 Number

- 8138.0 INR/Number

Industrial-Strength Press Mounting Solutions, Series-RBD-RT Product Specifications

- REDUCING VIBRATION

- Load Capacity : 50 to 2800 kg/pc Kilograms (kg)

- Applications: red_arrow_bullet Power Presses red_arrow_bullet Forging Hammers red_arrow_bullet Fans red_arrow_bullet Blowers red_arrow_bullet Generating Sets red_arrow_bullet Centrifuges red_arrow_bullet Test Beds red_arrow_bullet Textile Machines red_arrow_bullet Reducing Mills and Mixers red_arrow_bullet Coal and Stone Crushers red_arrow_bullet Refrigeration Units red_arrow_bullet Pumps and Boilers etc. red_arrow_bullet All types of heavy industrial machinery

- Iron, Rubber, Natural Rubber, synthetic rubbers

- BLUE

- REDUCING VIBRATION

- Size: , Hi - 98 to 108 mm, Bolt Size:M12

- ALL INDUSTRIAL SETUPS

- Hi - 98 to 108 mm, Millimeter (mm)

- ROUND AS PER PHOTO

- VIBRATION CONTROL

Industrial-Strength Press Mounting Solutions, Series-RBD-RT Trade Information

- RAI

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Days after Acceptance (DA), Cheque

- 1000 Number Per Day

- 2 Days

- Contact us for information regarding our sample policy

- Corrugated Box

- Western Europe, Eastern Europe, Middle East, Africa, Central America, South America, Australia, Asia, North America

- Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

- ISO 9001:2015

Product Description

Dynemech Spring Isolator

Dynemech is providing anti vibration solutions to the Indian Industry for the last 10 years. We are the only company to provide almost all types of vibration control solutions under one roof. Our product range consists of stud mounts for very small machines to wedge mounts for precision machine tools, along with air springs for very low natural frequency vibration damping to spring isolators for heavy presses, hammers, gen sets etc. A spring isolator gives desired natural frequency to obtain phase difference in the frequencies for a rotating machine. Viscous Damping is an important feature of an isolation system. In most cases viscous damping is required to limit excessive movement which could occur as a machine operates at a speed near to, or coinciding with the resonant frequencies of the system. Generally this problem arises during slow run up and run down of rotating machines and during impact at each stroke in presses and hammers.

Advantages of Spring Isolators:

|

The numerous benefits associated with the use of spring vibration isolators are: |

|

Applications: |

| The Springs are made in top grade wire & finished with protective coatings thus ensuring trouble free service life. |

| Selection Procedure |

Engineered for Reliability

With load capacities from 50 to 2800 kg per mount, the Series-RBD-RT is built to support various machinery, from lighter assemblies to extremely heavy-duty setups. The integration of high-grade iron and reinforced rubber materials amplifies durability and extension of service life in challenging environments.

Vibration Reduction Technology

Our mounts feature an advanced round spring housed in premium rubber, optimizing vibration isolation. This significantly reduces wear and tear on your machines and the supporting infrastructure, contributing to quieter, more efficient operations and improved safety on the workshop floor.

FAQs of Industrial-Strength Press Mounting Solutions, Series-RBD-RT:

Q: How do the Series-RBD-RT mounts reduce vibration in industrial machinery?

A: The Series-RBD-RT mounts utilize a specialized round spring encased in high-quality rubber and iron construction, which effectively absorbs and dissipates vibrational energy. This mechanism significantly reduces transmission of vibrations from operating machinery to the floor or adjacent equipment.Q: What machinery and applications are suitable for these mounts?

A: These mounts are ideal for a broad spectrum of heavy industrial applications, such as power presses, forging hammers, fans, blowers, generating sets, centrifuges, textile machines, reducing mills, stone crushers, refrigeration units, pumps, boilers, and other similar equipment.Q: When should I consider installing these mounting solutions?

A: It is best to install these mounts during new equipment setup or when upgrading existing machinery to enhance operational stability, reduce maintenance intervals, and extend overall machinery life. They are particularly useful whenever vibration or noise poses an operational challenge.Q: Where can the Series-RBD-RT mounting solutions be used?

A: They are suitable for use in all industrial environments across manufacturing, processing, energy generation, and heavy machinery sectors in India and globally, wherever vibration reduction and sturdy mounting are needed.Q: What is the installation process for these mounts?

A: The installation involves mounting the equipment with the provided M12 bolts, ensuring the mounts are correctly positioned based on the load distribution. Proper alignment and secure fastening maximize vibration reduction and operational effectiveness.Q: What are the benefits of using vibration-reducing mounts for industrial equipment?

A: By reducing vibrations, these mounts extend machinery lifespan, decrease noise levels, lower maintenance costs, and improve operator safety and machine accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese