Machinery Mounting Pads

Product Details:

- Material Steel

- Function Easy To Use

- Product Type VIBRATION CONTROL

- Usage For Laboratory And Industrial Use

- Weight Load (Kg/pc) 1400 Kgs Kilograms (kg)

- Color Green

- Click to View more

Machinery Mounting Pads Price And Quantity

- 1630 INR/Piece

- 100 Piece

Machinery Mounting Pads Product Specifications

- Easy To Use

- Green

- Load (Kg/pc) 1400 Kgs Kilograms (kg)

- Steel

- VIBRATION CONTROL

- For Laboratory And Industrial Use

Machinery Mounting Pads Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 100 Piece Per Day

- Days

- Corrugated Box & Wooden Box

- Himachal Pradesh, Kerala, Tamil Nadu, Andhra Pradesh, Rajasthan, Manipur, Tripura, Haryana, South India, Bihar, Uttarakhand, Chandigarh, East India, West India, Arunachal Pradesh, Assam, Jammu and Kashmir, Nagaland, Andaman and Nicobar Islands, Jharkhand, Mizoram, West Bengal, Pondicherry, Punjab, Sikkim, Central India, Karnataka, Telangana, Daman and Diu, , Goa, Uttar Pradesh, Odisha, North India, Maharashtra, Chhattisgarh, Lakshadweep, Gujarat, Dadra and Nagar Haveli, Delhi, Meghalaya, Madhya Pradesh, All India

- ISO 9001:2015

Product Description

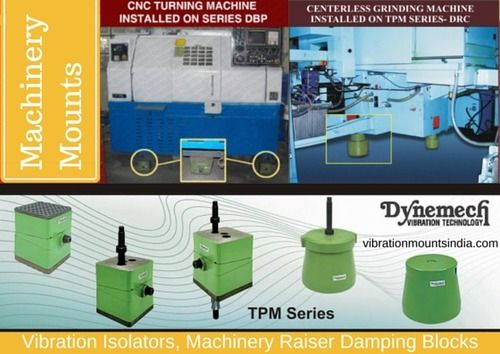

MACHINERY INSTALLATION AS PER TPM NORMS/MACHINERY MOUNTING PADS

In order to be globally competitive, Indian machine tool industry manufactures must improve the performance of the machine tool to meet customer demand. One such aid is anti vibration pads, as vibration are inherent in most of the machine too. DYNEMECH MACHINERY RAISER DAMPING BLOCKS find application in machines viz. Machining/Turning Centres, Grinding Machines, Power Presses, Pressure Die Casting Machines, Plastic Injection Moulding Machines, Tool Room Machines, Measuring and Testing Machines/ Equipments. Powder/Bottle Filling Machines, Packaging/Printing Machines, Pharmaceutical Machines, Textile Machines, Compressors, Gen. Sets, forging hammers etc.

They offer easy and quick installation of all type of machines. These blocks offer both levelling and vibration damping besides raising height of the machine for proper cleaning and repairing under it. Raiser Damping Blocks are assembled with insulation plates for vibration reduction. They provide fast and easy installation, flexible shop floor plan, enhanced component finish/part tolerance, extended tool and machinery life, improved health protection, better structural safety. Ideal for CNC Turning/Machining Centres, Cylindrical & Centreless Grinding Machines, Precision Machine Tools.

These mounts help implement TQM norms for machine installation. Proper maintenance, cleanliness, vibration reduction results in enhanced machine tool reliability (zero breakdowns), reduced operation and life cycle costs which are the driving factors for adoption of Total Productive Maintenance (TPM) practices. Machines are installed at a height of 100-150mm which help implement TPM norms for machine installation as recommended by IMTMA.

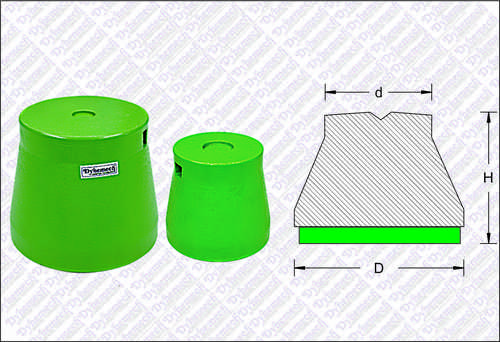

DYNEMECH Series DR , are suitable for machines having tapped hole in the base.The bolt rests over the dimple provided on the top face of the mount. Dimple size is provided as per the bolt diameter in the machine base.

DYNEMECH RAISER DAMPING BLOCKS, SERIES DRC are suitable for

machines having plain hole in the base. Leveling is done by turning the bolt which lifts the cover plate along with the machine.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese